Taking back used stone wool from the market via Rockcycle

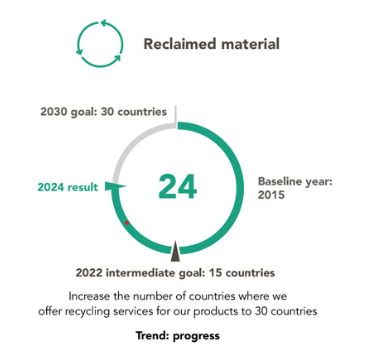

It’s now available in 24 countries and our aim is to reach 30 by 2030*. How it works is fairly simple. We take back stone wool material from construction, renovation and demolition sites and recycle it in our production process to make new ROCKWOOL products.

Why is that important? Because the construction industry has a waste problem. Valuable materials are too often uncollected and misdirected to general waste, which ends up in landfill. In fact, only 20–30 percent of construction and demolition waste (CDW) is recovered at all1, indicating the urgent need to tackle this problem.

Our sustainability goals relating to circularity

Check out Rockcycle in your country

Austria

Belgium (NL) & Belgium (FR)

Canada

China

Croatia

Denmark

Finland

France

Germany

India

Italy

Luxemburg

Malaysia

Netherlands

Norway

Poland

Slovenia

Spain

Sweden

Singapore

Switzerland

Romania

UK

US

or specifically for three of our systems; Rockfon (NL) / (UK)/ (US)

Rockpanel (DK)/ (NL)/ (DE)/ (BE)/(FR) and; Grodan