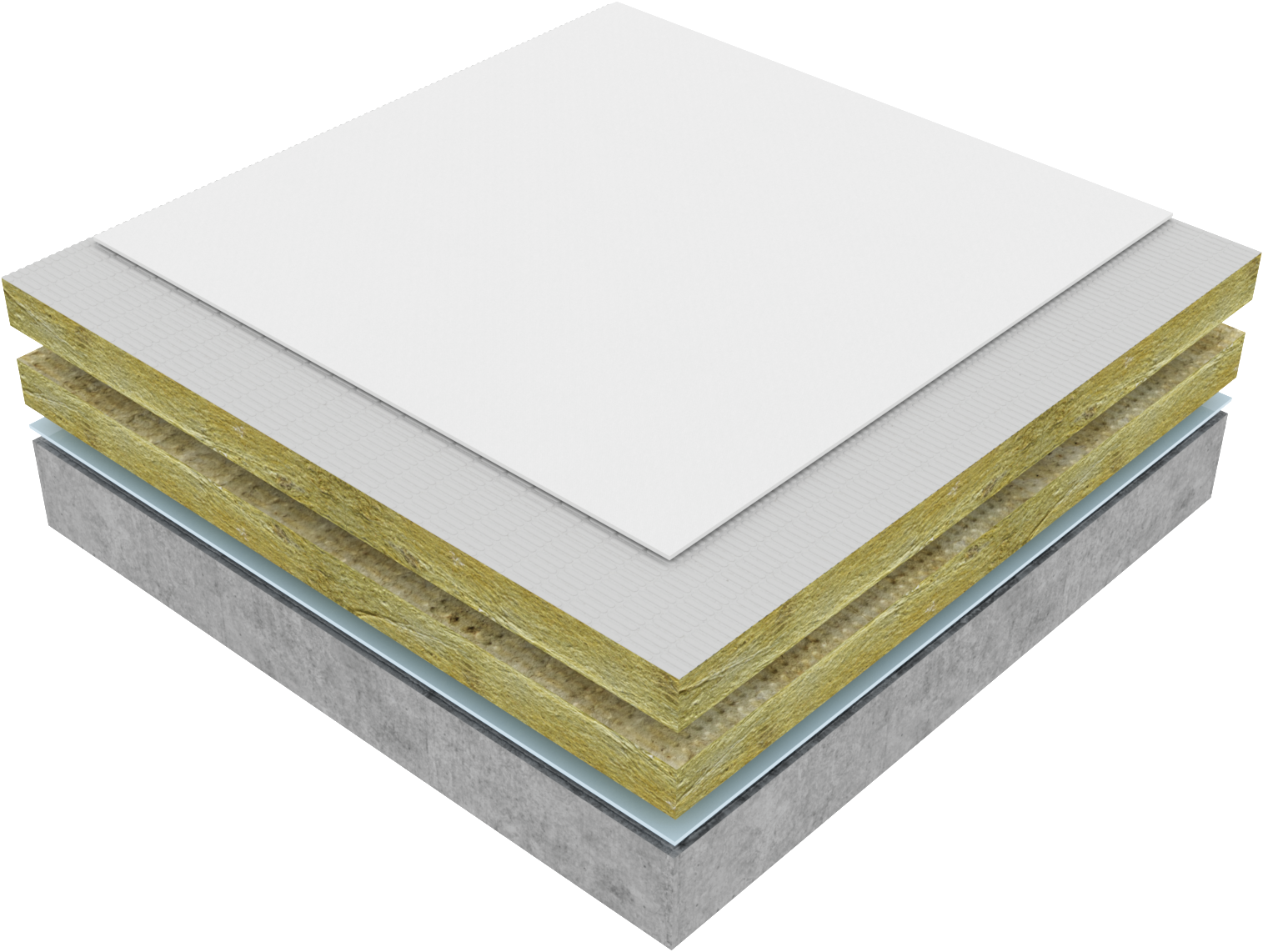

When designing and building a roof system, achieving the greatest performance and resilience comes from selecting the right products for your project. ROCKWOOL low slope roof insulation products can be used to help minimize the fire, sound and long term performance risks of your project.

With numerous ROCKWOOL stone wool products available, you will find insulation options that support optimizing system cost, thermal performance, fire and acoustic resistance and long term durability.

Fire resistant:

Noncombustible, stone wool roof insulation products can be used in Class 1 roof deck construction and are classified as a non combustible core (NCC) roof insulation under FM 4470.

ROCKWOOL roof products are suitable for WUI zone construction, and are listed within the California Office of the State Fire Marshall’s Building Materials listing.

Learn more about CAL FIRE listings

Sound absorbent:

The non-direction fiber orientation and increased mass effectively reduces sound transmission, with performance that conforms to the 2015 International Green Construction Code’s OITC and STC requirements for buildings in close proximity to high noise sources

Find acoustic rated low slope roof solutions in out assembly catalog.

Download our roof acoustic catalog

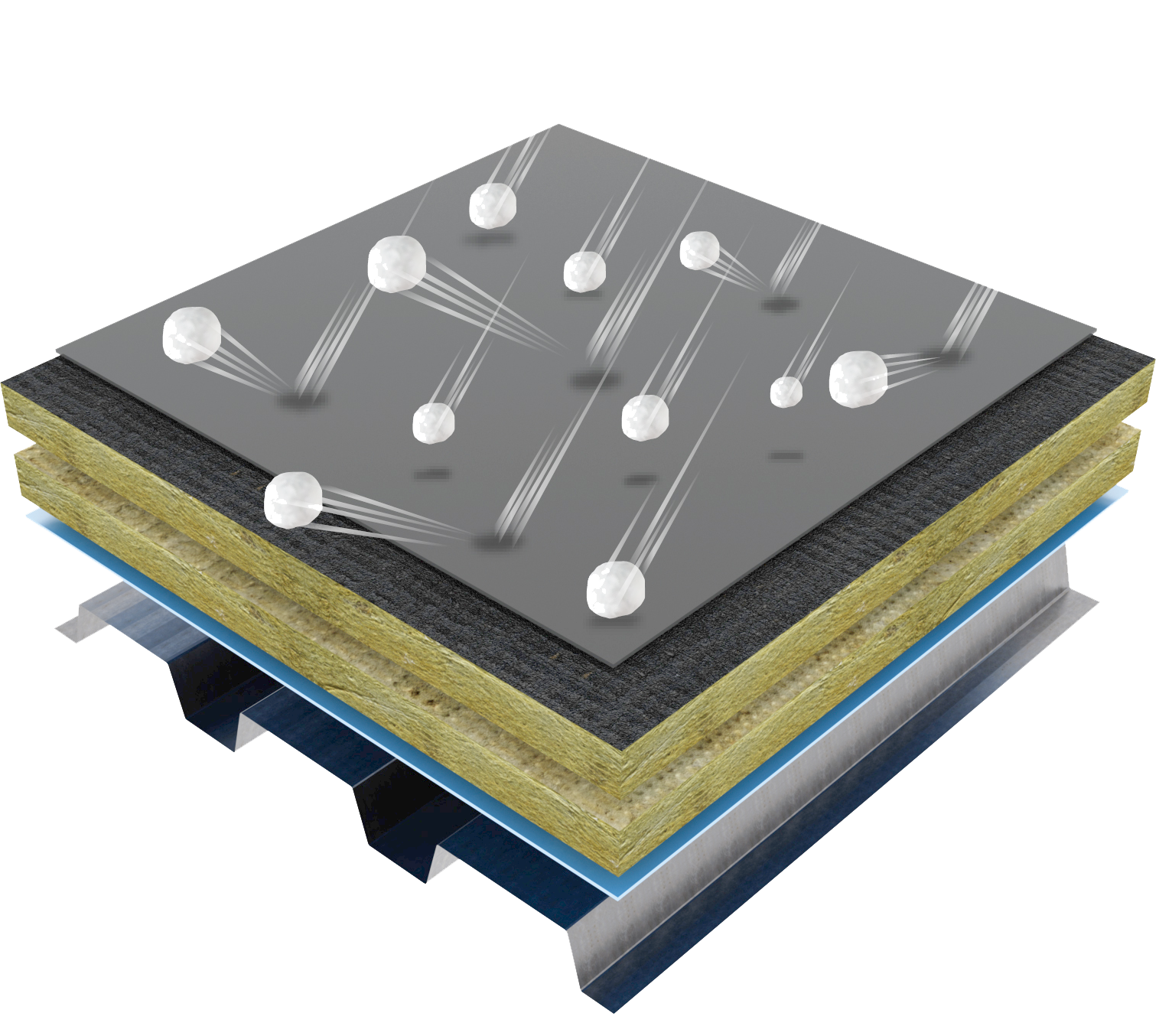

Durable:

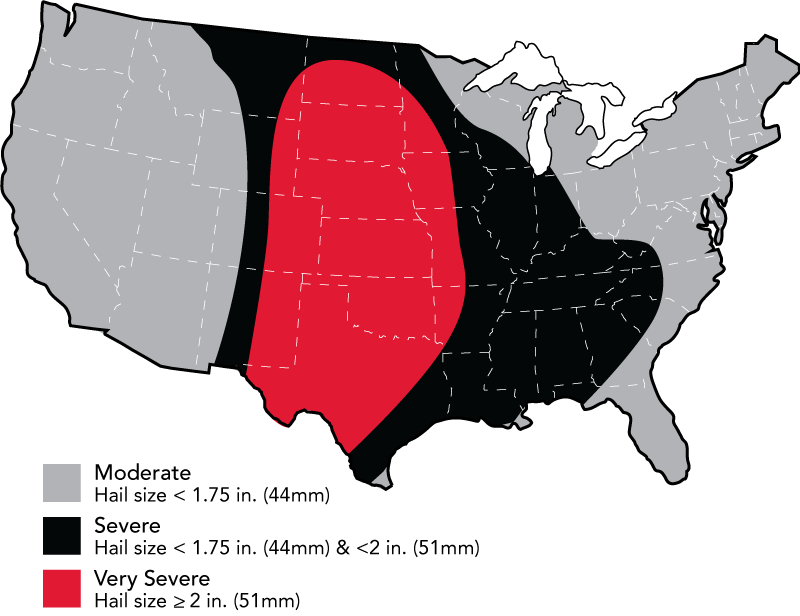

Dimensionally stable and providing long term thermal efficiency, stone wool roof boards maintain their structural integrity even when exposed to hail and wind.

ROCKWOOL roof board products have been tested for severe and very severe hail (VSH) and is acceptable as a coverboard in VSH regions.

Learn more about stone wool insulation and VSH testing

Vapor-permeable and moisture-resistant:

Structural integrity of stone wool insulation boards are not affected by the presence of water, and the vapor permeability of stone wool can benefit a roof assembly designed to promote drying

Sustainable:

Stone wool insulation is manufactured from one of the world’s most abundant raw materials without the use of blowing agents or toxic flame retardants, stone wool can contribute towards LEED credits for your project