Multifix™

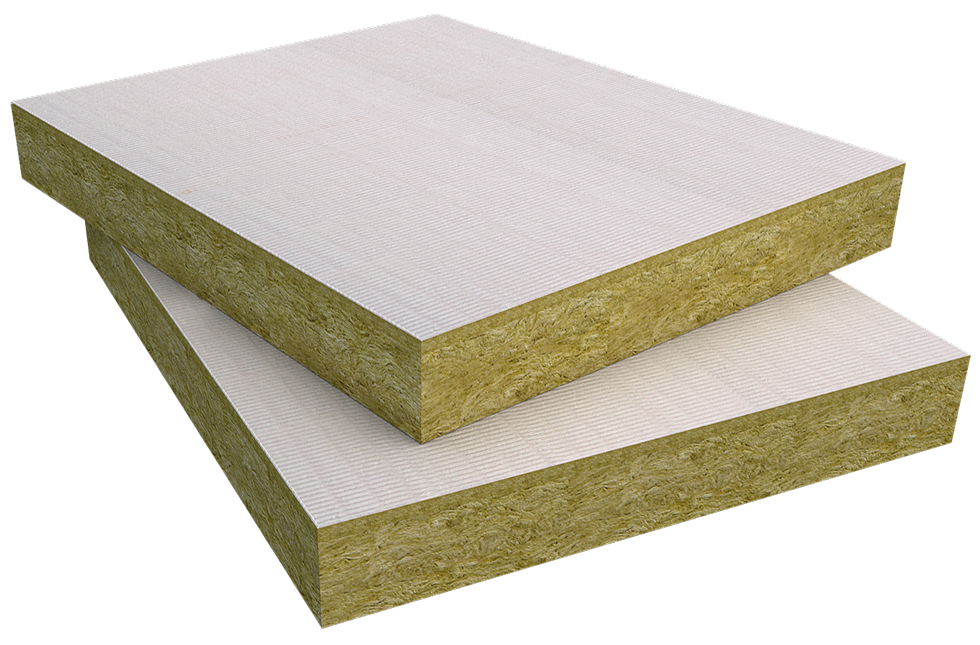

ROCKWOOL Multifix™ is a high-density insulation board with a mineral-coated fiberglass facer for low-slope roof applications. It is compatible as the substrate for torched, hot mopped, self-adhered, cold-adhered, and liquid membrane systems.

1/1

Popular applications

- Roof insulation

- Low slope roof insulation

About this product

ROCKWOOL Multifix™ is a stone wool insulation board with a mineral-coated fiberglass facer, designed for low-slope roof applications. Multifix is compatible with torched, hot mopped, self-adhered, cold-adhered, and liquid applied membrane systems.

Noncombustible, Multifix will not develop toxic smoke or promote flame spread even when directly exposed to fire. Also offering improved sound absorbency and dimensional stability, Multifix is designed to maintain long-term thermal and acoustic performance.

- Noncombustible and fire resistant

- NCC (Non Combustible Core) Rated Roof Insulation

- Liquid applied, cold adhered membrane solutions

- Water and moisture repellent

- Dimensional stability to maintain performance

- Excellent acoustic performance

Why use stone wool insulation

- Stable long-term R-values for superior thermal performance.

- Made from naturally fire resilient stone, ROCKWOOL insulation will not develop toxic smoke or promote flame spread, even when exposed to a fire.

- Stone wool provides excellent noise reduction and sound absorption to help you create quieter, more productive environments.

- Water resistant, stone wool does not rot or promote the growth of mildew, fungi or mold.

- The manufactured dual-density boards provide increased compressive strength and point load resistance to minimize puncture damage from foot traffic and severe weather.

- Dimensionally stable, stone wool does not expand or contract due to temperature variances.

Applications

- Versatile insulation for flat roof applications.

- Direct-to-deck installation simplifies process.

- Cold-adhered assemblies, including TPO, PVC and KEE membranes.

- Torch or hot adhesive membranes.

- Liquid applied membrane assemblies.

Product certificates

Miami-Dade County Approved

Miami-Dade County Approved FM Approved

FM Approved UL Classified - CA/USA

UL Classified - CA/USA

Multifix™ sizes, dimensions & packaging

Find Multifix™ thickness, width, length and pack quantities—everything you need for accurate specification and ordering.

- All

- 2

- 3

Specifications & testing

Explore Multifix™ specifications and test results, based on relevant industry standards.

| Name | Value | Unit | Test standard |

|---|---|---|---|

| NCC (Non Combustible Core) Rated Roof Insulation | Passed | FM 4470 | |

| Flame spread index | 0 | ASTM E84 | |

| Smoke Developed Index | 0 | ASTM E84 | |

| Combustibility of Materials at 750 °C | Non-combustible | ASTM E136 | |

| Determination of Non Combustibility of Building Materials | Non-combustible | CAN/ULC S114 | |

| Fire Tests of Roof Coverings | Class A | CAN/ULC S107-03 | |

| Heat Release Rate of Roofing Assemblies with Combustible Components | Class 1 | NFPA 276 | |

| Corrosion of Steel | Passed | ASTM C665 | |

| R-Value / inch @ 75 °F | 3.8 | hr.ft².F/Btu | ASTM C518 (C177) |

| RSI value / 25.4 mm @ 24 °C | 0.67 | m²K/W | ASTM C518 (C177) |

Multifix™ technical documents & resources

Download Multifix™ technical documents and resources, including the product data sheet, to support accurate specification and efficient project planning.

Multifix flat roof insulation - Data sheet

Multifix™ is a rigid, high-density stone wool insulation product with a mineral-coated fiberglass facer that is compatible with multiple attachment methods including torched, hot-mopped, cold-adhered and liquid systems.

Multifix_072200 Roof and Deck Insulation GUIDESPEC EN_US

Multifix_072200 Roof and Deck Insulation GUIDESPEC EN_CA

Construction Details - Industrial Commercial Masonry Construction with Exterior Insulation up to 4 stories

Dimensional stability of rigid board insulation products

Investigations often uncover irreversible dimensional changes in rigid foam board insulation, like EPS, XPS, and ISO.

Guidelines for cutting stone wool insulation

Properly cutting stone wool insulation ensures fit and maintains performance, preventing safety and efficacy issues.

Enhancing metal roofing systems with stone wool insulation

Metal roofing panels are structural or architectural, each with unique functions and benefits, vital for building integrity and aesthetics.

Attend a ROCKonnect Masterclass

Earn CEUs and gain expert insights into high-performance building envelope design—all in a live virtual format built for commercial building professionals. Learn from award-winning experts and apply real-world solutions to your next project.

Product support & insights

From expert technical guidance to real-world case studies and certified sustainability documents, access the tools and insights that support confident, high-performance building with stone wool insulation.