Full Fill Cavity Batt

ROCKWOOL® Full Fill Cavity Batt is a semi-rigid, non-combustible, BBA-approved insulation product for masonry cavity wall constructions.

1/3

Application(s)

- External Wall

- Cavity Wall

- Internal Wall

- Separating Walls

Product description

ROCKWOOL Full Fill Cavity Batt is a semi-rigid stone wool insulation batt for the thermal insulation of external masonry cavity walls and for the thermal insulation and acoustic protection of masonry party walls between dwellings.

Other than in very severe exposure locations with fair-faced masonry, the NHBC accepts the use of ROCKWOOL Cavity Batt in relation to NHBC Standards, Chapter 6.1, External masonry walls, provided it is installed, used and maintained in accordance with the BBA Certificate.

*Subject to application

- Euroclass A1 in accordance with BS EN 13501-1 Reaction to Fire rating

- Thermal conductivity 0.037 W/mK

- BBA approved (Certificate No. 94/3079)

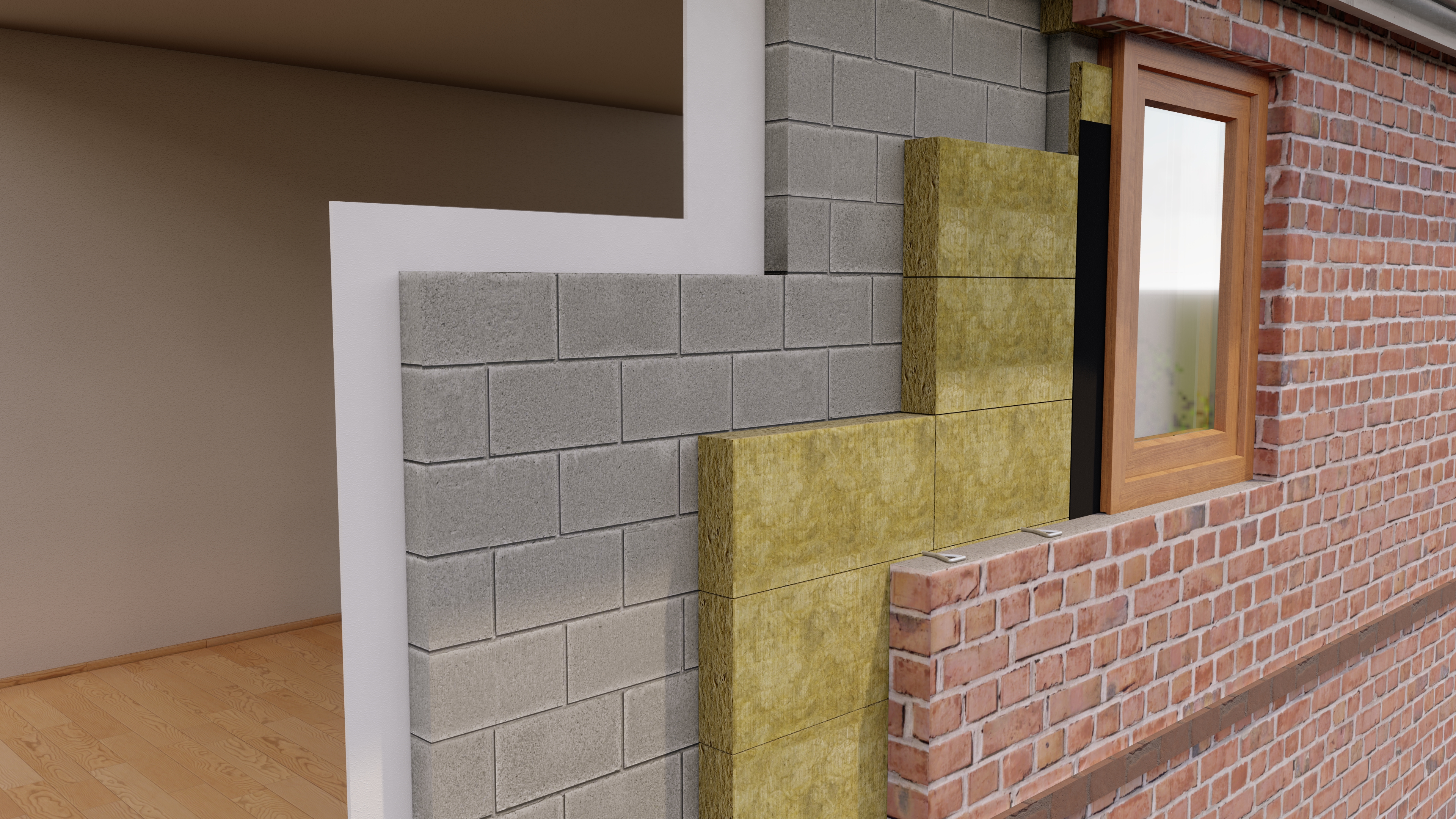

Areas of application

Applications for the Full Fill Cavity Batt are:

- Thermal insulation of external masonry cavity walls

- Thermal insulation and acoustic protection of masonry party walls between dwellings

Download Documents

If you require any certification that is not listed here, please contact us via ukdocumentation@rockwool.com

Full Fill Cavity Batt Datasheet

ROCKWOOL® Full Fill Cavity Batt is a semi-rigid, non-combustible, BBA-approved insulation product for masonry cavity wall constructions.

Full Fill Cavity Batt BBA Certificate

Certificate No. BBA-94-3079-Full Fill Cavity Wall Insulation

ROCKWOOL Stone Wool BSI Kitemark Certificate

Certificate No. km06661-bs-en-13162-2012-a1-2015

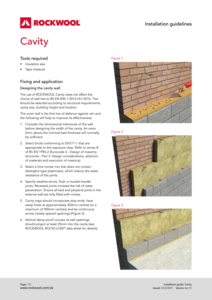

Cavity Batt Installation Guide

Installation guideline for Cavity Batt ROCKWOOL Products

SUIS ROCKWOOL UK

Safe use instruction sheet ROCKWOOL stone wool insulation products

Product properties

| Name | Value | Test standard | Symbol | Unit |

|---|---|---|---|---|

| Declared thermal conductivity | 0.037 | EN 12667 | λD | W/mK |

| Reaction to Fire | A1 | EN 13501-1 | Euroclass | |

| Long term water absorption | WL(P) | EN 12087 | WL(P) | kg/m² |

| Short term water absorption | WS | EN 1609 | WS | kg/m² |

| Product standard | EN 13162:2012+A1:2015 | |||

| CE certificate number | 0751-CPR-393.0-01 | n/a | ||

| Declaration of Performance (DoP) number | UK-WER-0009-02 | |||

| BBA certificate number | 94/3079 | n/a | ||

| KEYMARK certificate number | 003–SDG-5-477232 |

Product variants

Full Fill Cavity Batt Installation Guide

Before beginning installation, assemble tools such as an insulation saw, tape measure and PPE (personal protective equipment) such as gloves/mask if working in an unventilated area, and eye protection when working overhead. Cover all exposed skin. Carry out a pre-work safety check, identifying any potential hazards such as:ease of access, work heights, trip hazards, electrical safety

1/10

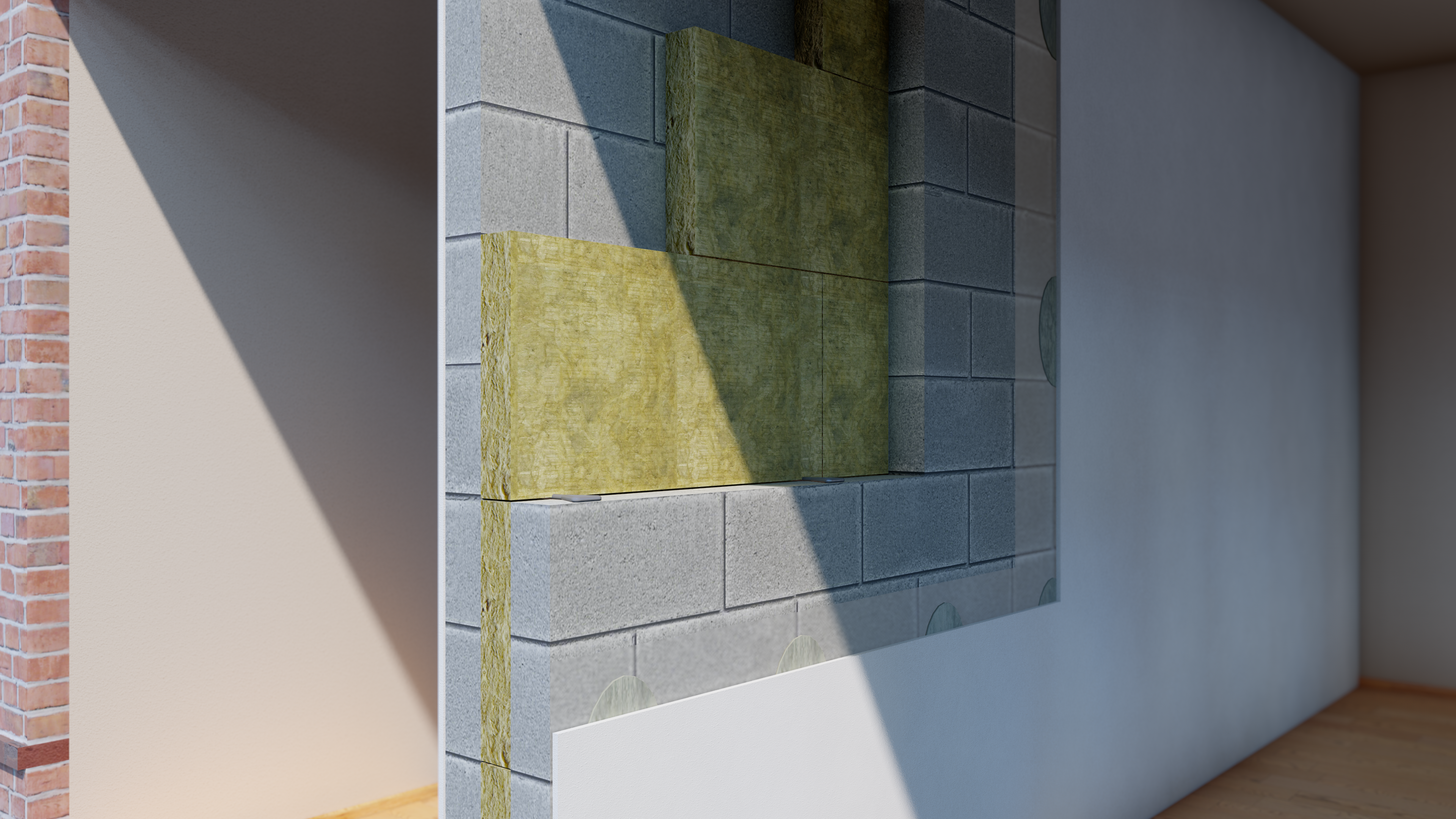

- Step 1 of 10: Step 1 - Cut the batts cleanly

- Step 2 of 10: Step 2 - Install the batts below the DPC

- Step 3 of 10: Step 3 - Positioning the batts

- Step 4 of 10: Step 4 - Fixing the batts

- Step 5 of 10: Step 4 - clean off any protruding mortar

- Step 6 of 10: Step 6 - Securing the batts

- Step 7 of 10: Step 7 - Ensure batts are tightly butted

- Step 8 of 10: Step 8 - top edge must be protected by a cavity tray

- Step 9 of 10: Step 9 - completing corner joints

- Step 10 of 10: Step 10 - multilayering insulation

Step 1 - Cut the batts cleanly

Cut the batts cleanly, using a sharp, long bladed knife and a straight edge. It isessential that cut pieces of batts completely fill the spaces for which they are intended and are adequately secured. Gaps must not be left in the insulation.

Looking for answers?

Whether you need help finding a local stockist, have a technical question, or want to speak with a sales representative, we’re here to help. Choose the option that best fits your needs.